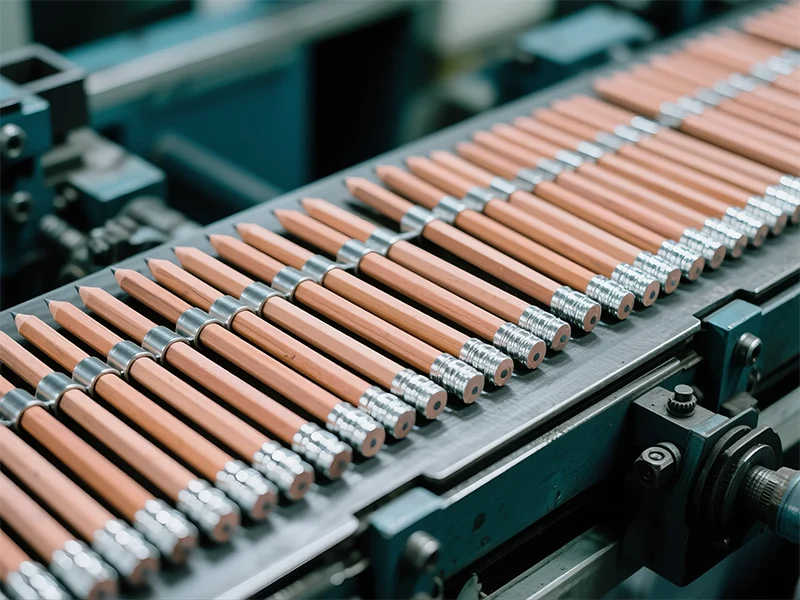

Recently, Sanjing Hardware, a leading Chinese manufacturer of stationery metal accessories, announced the official launch of its fully automated pencil ferrule production line in Zhenjiang, China. The line utilizes intelligent robotics and precision stamping technology, significantly improving production efficiency and product accuracy, providing high-quality accessories for global stationery brands.

Technological Leadership: 300% Efficiency Boost, Precision of ±0.1mm

Traditional pencil ferrule production relies on manual labor, but Sanjing Hardware’s new line adopts “multi-station progressive stamping technology,” integrating blanking, forming, and polishing processes. It can produce over 200 pieces per minute, increasing efficiency by 300%. Additionally, high-precision molds and automated quality control ensure tolerances within ±0.1mm, guaranteeing consistency and durability.

Technical Director of Sanjing Hardware, stated, “We use high-quality stainless steel and eco-friendly coating processes to enhance corrosion resistance and meet global environmental standards.”

The production line features waste recycling systems and energy-saving equipment, achieving 98% metal utilization and wastewater recycling. Currently, Sanjing Hardware’s pencil ferrules are exported to over 20 countries, including the U.S., Europe, Japan, and South Korea, with an annual capacity exceeding 300 million pieces, making it a long-term supplier for top global stationery brands.

Industry analysts noted that Sanjing Hardware’s automation upgrade will drive China’s stationery accessory sector toward advanced manufacturing, enhancing the global competitiveness of “Intelligent Chinese Manufacturing.”